FT 277/2

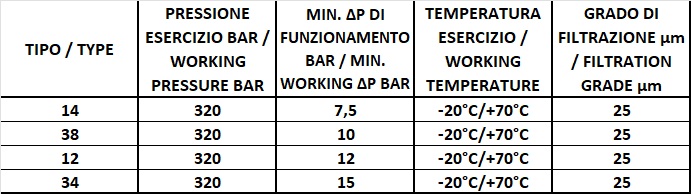

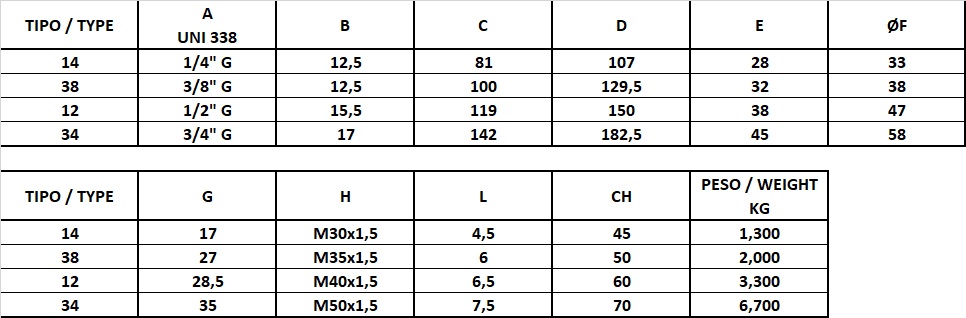

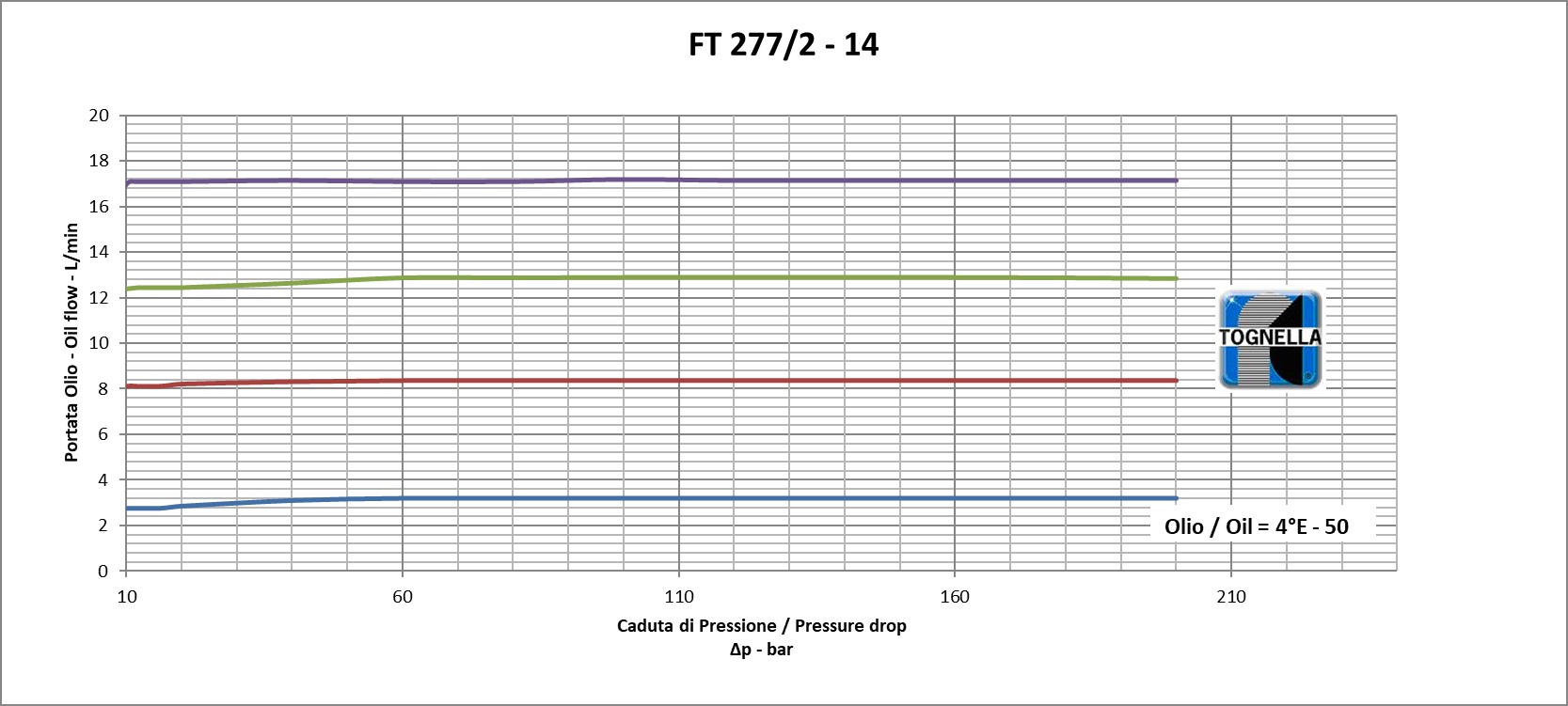

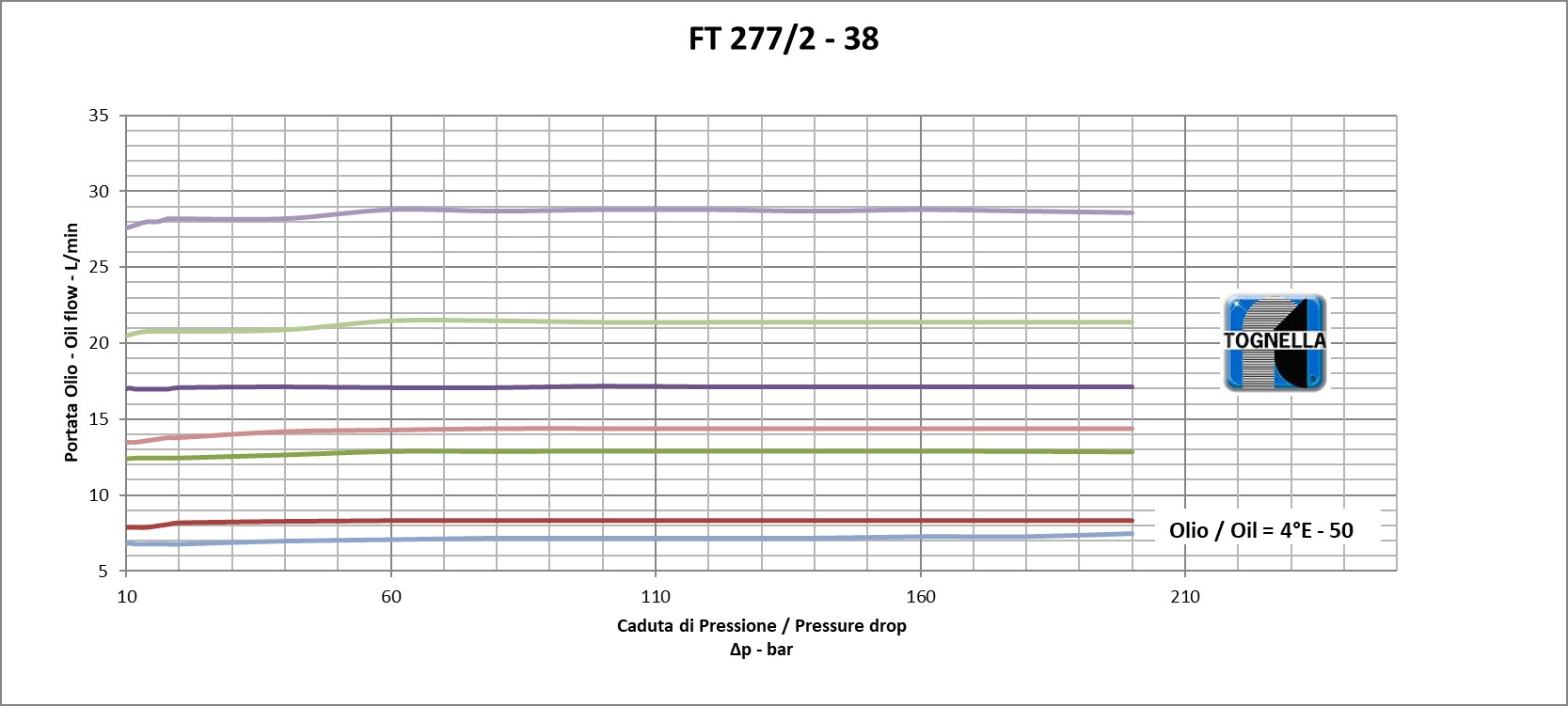

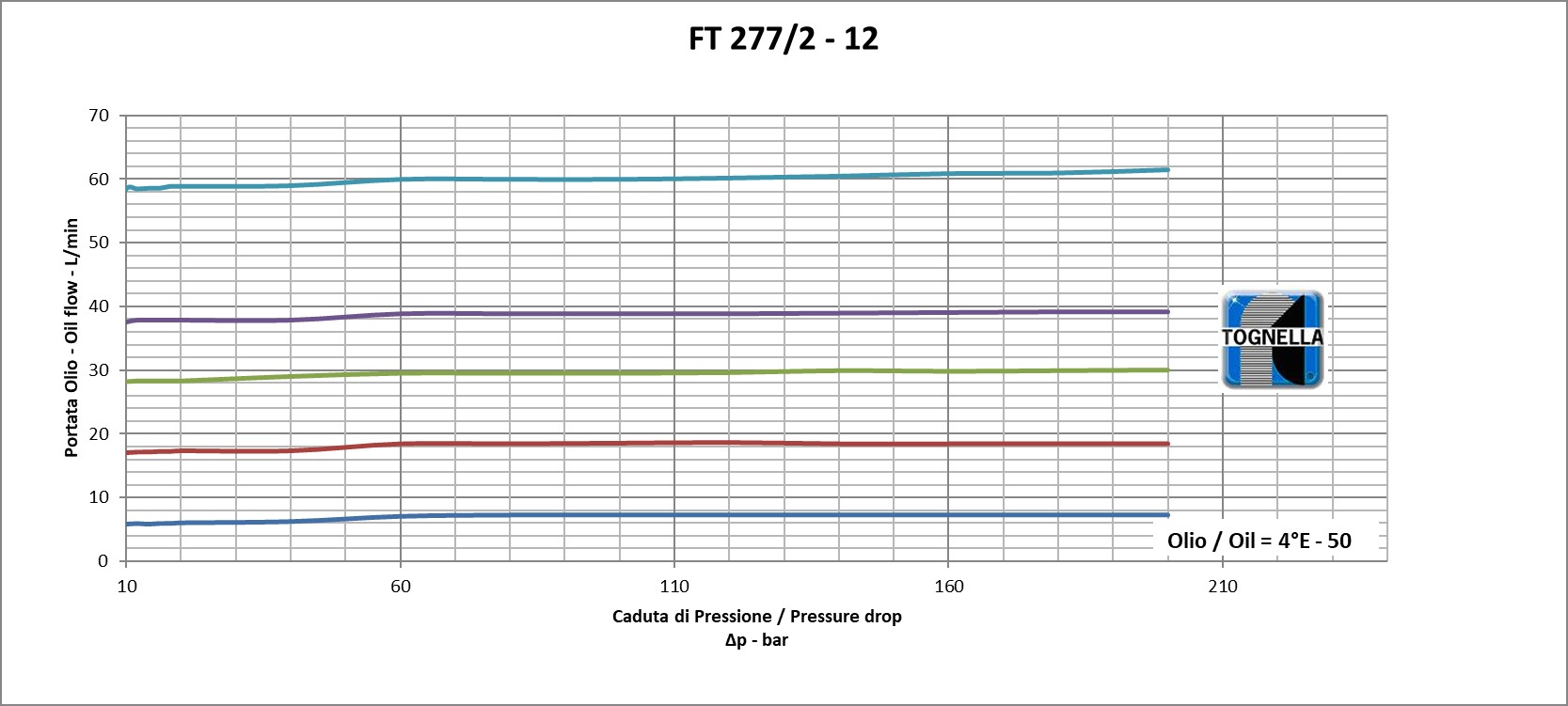

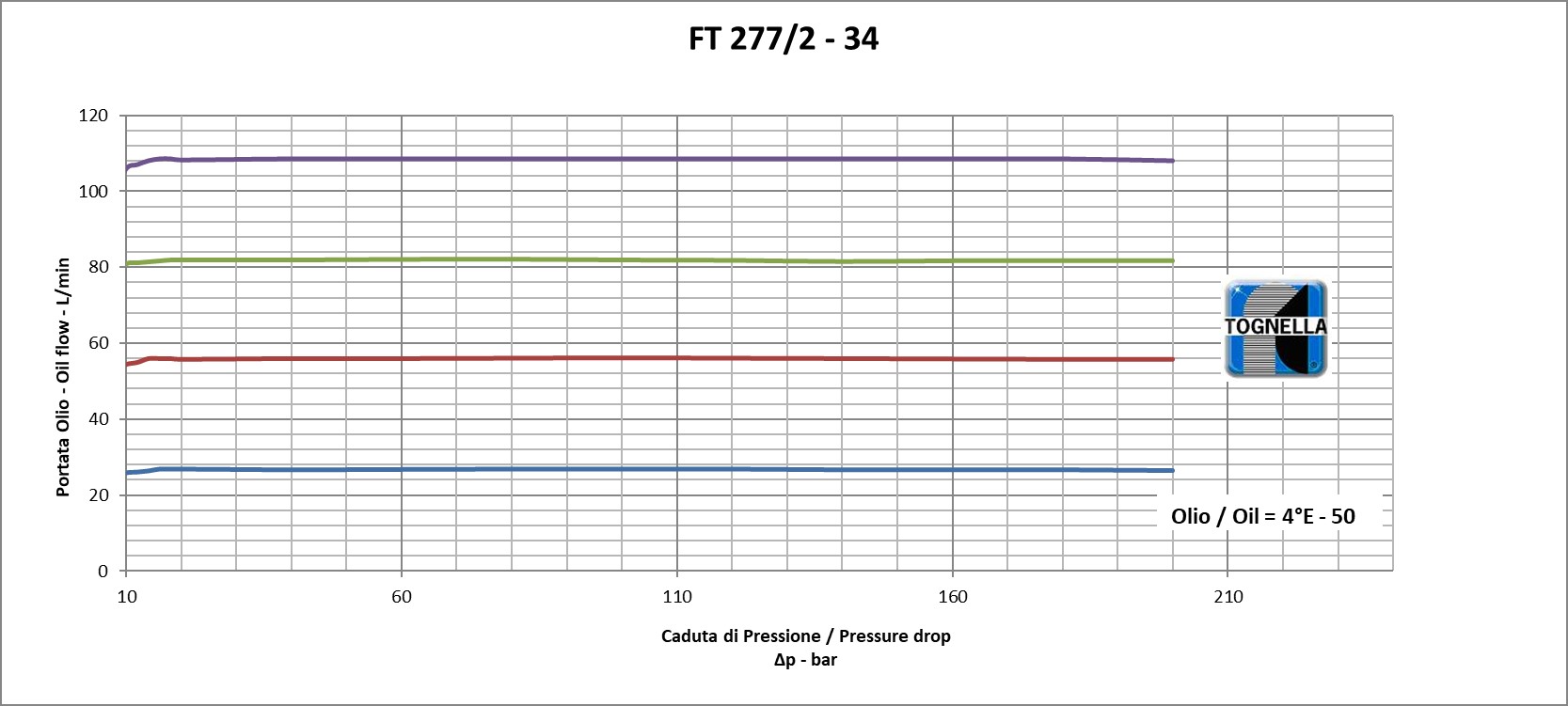

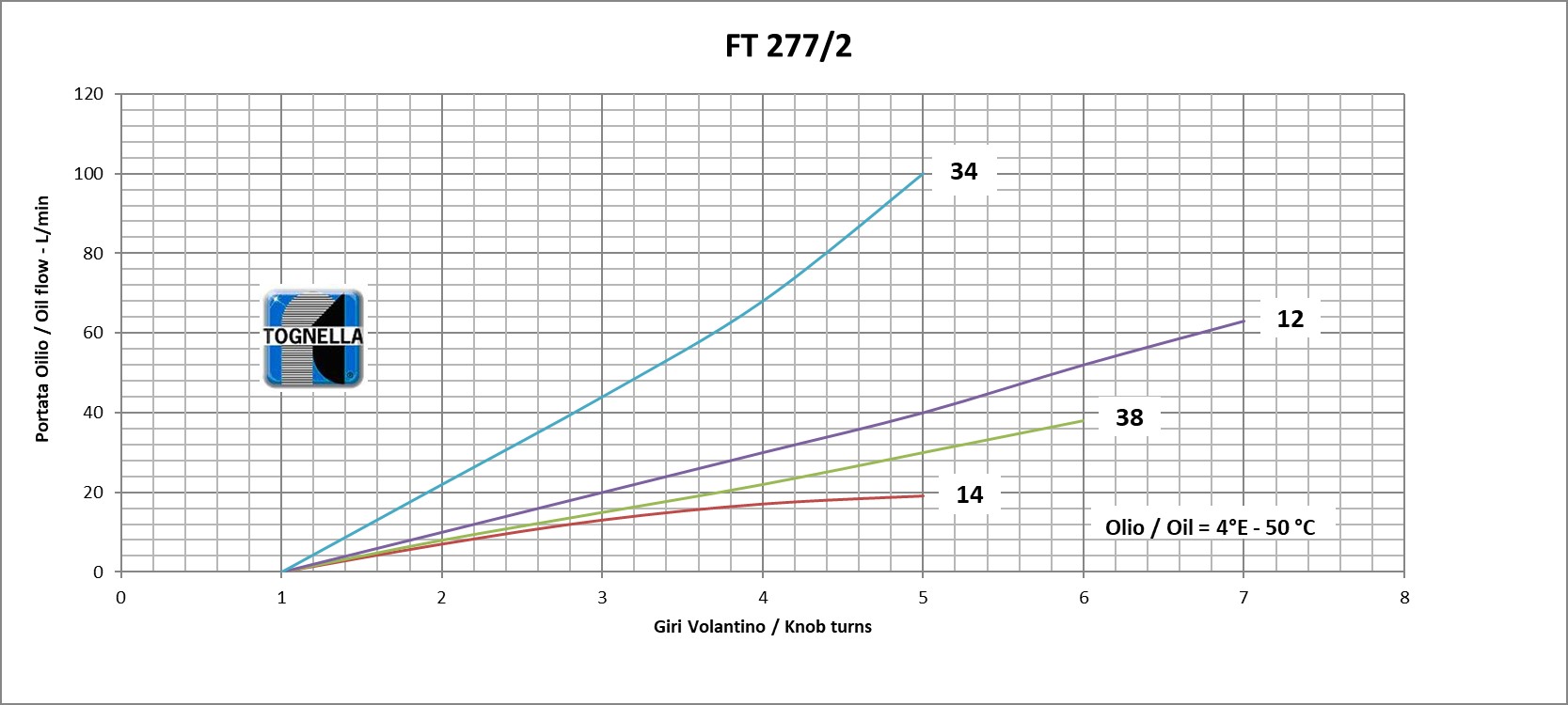

Compensated double-acting flow control valves available from 1/4" to 3/4" BSPP size, max. working pressure 320 Bar, adjustable oil flow rate from 5 to 75 Lt./min. ( depending on the size ) - Precision in compensation +/- 1% max

Product code composition

Choose the different options below to configure the most useful product code for your needs.

The code will be generated and sent automatically by clicking on "Submit a request".

* (BSPP - standard)

NPT

* (NBR - standard)

** (V - FPM - standard for stainless steel valves)

E

(EPDM)

N (NEOPRENE)

S

(SILICONE)

V (FPM)

* (MA - standard - aluminium)

MP

(ABS)

RA

(Aluminium spoked)

* (no nut)

G

(nut)

The request can be sent only upon completion of all the choice fields

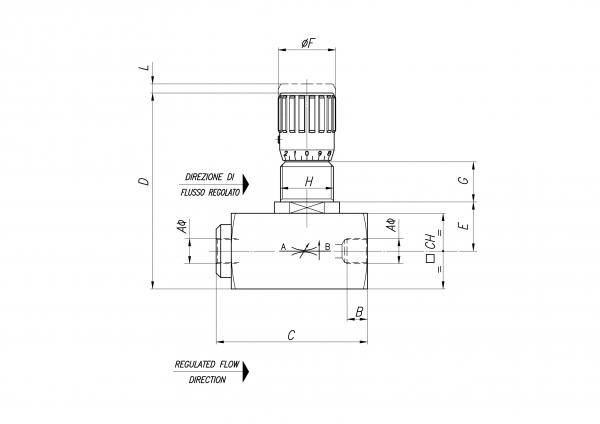

Technical information

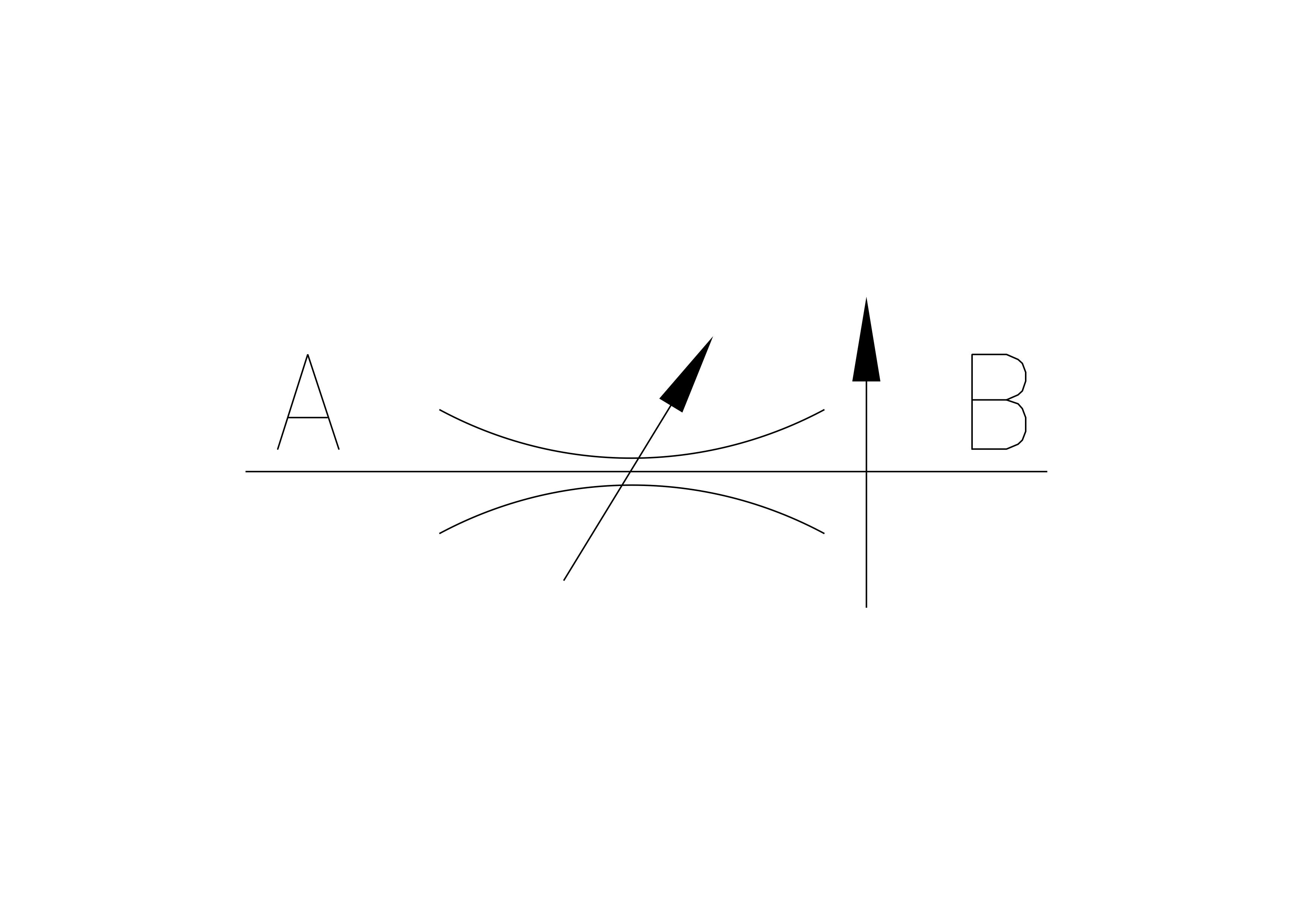

Double-port pressure compensated control valves. They include two necks in series: • the first one with port section definable by an external control; • the second one with automatically variable section according to the counter-pressure variations on use. The choice of the adjustable neck situated upstream is the one that best ensures the precision of the valve towards fluid temperature variations. Regarding the structure of the valve, the following points must be underlined: • the rigorous symmetry of the internal components such as to prevent unforeseen perturbations of the static and dynamic balances; • the arrangement optimisation of internal spring controlling the intervention of the automatic throttling, at variable preload, with throttling fixed settings , useful to improve the behaviour at medium-high flow rates; • the geometry of the passages across which the flow is automatically throttled, designed to minimize the effect of the flow hydromechanics forces on the total balance of the moving element; • the accuracy of the machining which enabled to cancel any hysteresis effect of mechanical origin; • the original aesthetic feature, underlined by the particular form of the control knob; • the easiness to reset the flow value thanks to reference pointers. Moreover we believe important to underline the choice of the constructive solution fitting to the concept of “double valence”, according to which, the central body, configurated as a threaded cartridge and insertable in the two different bodies at the base or directly in standard modular units, creates the three traded versions: • FT 277/2 two-way • FT 277/5 two-way with check valve • threaded cartridge FT 287/2. This solution enables the user to eventually request the single modular components to be assembled according to the current need. Precision in compensation ± 1% of the flaw rate.